FACTORY

Shikhar Foods has 3 plants capable of processing 480 Metric Tons of paddies per day. We can ship one container every two hours. Whether you need 20 tons or 2,000, we can serve your export needs for shipment in break-bulk or containers with speed and accuracy, as well as quality assurance. Here are the latest photos of our Rice mill.

| Mill No. 1 Address of Rice Mill : Shikhar Foods Pvt Ltd Unit 1, Adda Bazar, Nautanwa DistMaharajganj – 273164 Uttar Pradesh, INDIA Processing Capacity : 96 metric tons per day Started & Upgraded Year : Started in 1999 , Upgraded in 2014 Technology Used : Sea Pixel, Italy |

| Mill No. 2 Address of Rice Mill : Shikhar Foods Pvt Ltd Unit 2 , Sonauli Road , Village Sampatiha, DistMaharajganj- 273164 Uttar Pradesh, INDIA Processing Capacity : 144 metric tons per day Started & Upgraded Year : Started in 2005 , Upgraded in 2015 Technology Used : Satake, Japan |

| Mill No. 3 Address of Rice Mill : Shikhar Foods Pvt Ltd Unit 1, onauli Road , Village Sampatiha, DistMaharajganj- 273164 Uttar Pradesh, INDIA Processing Capacity : 240 metric tons per day Started & Upgraded Year : Started in 2009 , Upgraded in 2016 Technology Used : Sea Pixel, Italy |

Processing Equipments

Milling Separator

This all-purpose milling separator is used for the efficient separation of large coarse material and small fine materials such as grit during the cereal cleaning process.

Destoner

Destonersimplifies the cereal cleaning process. It removes high density impurities such as stones and separates materials into four groups by density: stones and other heavy impurities, whole clean grain, low density and damaged kernels, and dust.

Paddy Husker

The Paddy Husker is used for de-husking the paddy from the rice and other food grains. It is mainly used in paddy hulling and separating from rice husks with a mixture of paddy and brown rice.

Paddy Separator

The paddy separator machine is ideally equipped for separating pure brown rice from the grain mixture by taking advantage of differing gravity and surface frictional coefficients between brown rice and paddy rice. It is particularly suitable for separating mixed grain, effectively improving the purity of brown rice.

Thickness Grader

The Rice Thickness Grader is used to classify materials per size and thickness; It is mainly helpful for removal of oversized or undersized grains in one pass through, an effective way of separating non-matured and broken grains from the hull.

Rice Whitener

A vertical device with a special emery sharpening abrasive, used to whiten rice grains with minimum broken grains.

Rice Polisher

Abrasive machines that uses talc or other very fine abrasives to buff the outer surface of each rice kernel, making sure the surface of the milled rice is smooth and clean. This creates a better looking and better feeling rice.

Rotary Shifter

This machine can sift milled rice efficiently and accurately into 2 to 7 classes: large broken, medium broken, small broken, tips, bran, and the like. It is especially effective when there is a distinct size difference, for example when separating small broken pieces from rice bran..

Length Grader

A Length Grader is used to separate broken or shorter grains from whole grains. Length graders are indispensable for producing high quality products in rice milling and seed cleaning plants because of the difficulty in separating broken or shorter grains more than half the length of whole grains. These graders are able to determine size and length more accurately, producing a higher count of full long-grain rice hulls.

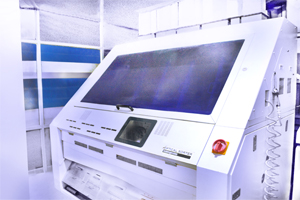

Rice Color Sorter

This equipment uses Satake Trichromatic Full Color Camera technology which enables it to see all colors as well as the human eye. The full color camera allows the machine to detect and sort grains with the smallest color differences and sort material with several color defects.

Semi-Automated Packaging

This semi-automatic packaging machine is used to accurately measure and package rice in bags of 5, 10, 25 and 50 Kgs.